WHY POLYSTYRENE PACKAGING

How our packaging is made

During transport, we protect our bottles from impacts and temperature changes with packaging consisting of two elements, made of two different materials:

- On the outside, a cardboard casing sealed with adhesive tape and staples: it completes and further protects the content, like a shell.

- On the inside, a core of expanded polystyrene (EPS): despite being light, it is a very strong material. And environmentally friendly.

The part in polystyrene has been specially designed for transporting bottles: fitted into ad hoc compartments, they remain still and in the correct position.

Why a polystyrene core?

Because the excellent performance of this material guarantees maximum protection from impacts and temperature changes – the two major dangers during transport.

Thanks to its molecular structure made up of 98% small air cushions, polystyrene (EPS)

- is resistant to compression and deformability – thanks to the elastic nature of its structure

- is an excellent thermal insulator – the very air it is made up of limits heat loss

- is very light – its light weight is an advantage when it comes to transport.

The features of polystyrene

Expanded polystyrene (EPS), the core of our packaging, has ideal features for guaranteeing the best protection from impacts and temperature changes.

- Excellent resistance to mechanical stress.

- It is waterproof, it resists humidity and water.

- It is inert, it doesn’t rot or mould.

- It is nontoxic, it doesn’t develop dioxin during combustion, it is not harmful.

- It is 100% recyclable.

Polystyrene is greener than it seems

According to an LCA study – which assesses the environmental impact of the processing, use and disposal of materials – polystyrene is the best material of all among those destined to the packaging industry in terms of eco-friendliness.

- Little water and energy are needed to produce it – less than cellulose pulp.

- Its lightness significantly reduces CO2 emissions during transport – one of the parameters for assessing the environmental impact.

- With correct disposal (it should be put with plastic) EPS is 100% recyclable and can be reused indefinitely.

How many lives!

Before disposal, our polystyrene packaging can be reused as a container for transporting wine, or as a wine holder for storing bottles. In this case, we recommend a well-ventilated environment with at least 70% humidity and a constant temperature between 12 to 16 degrees.

This temperature is also important during transport, not just for storage.

Our packaging: how to dispose of it or recycle it

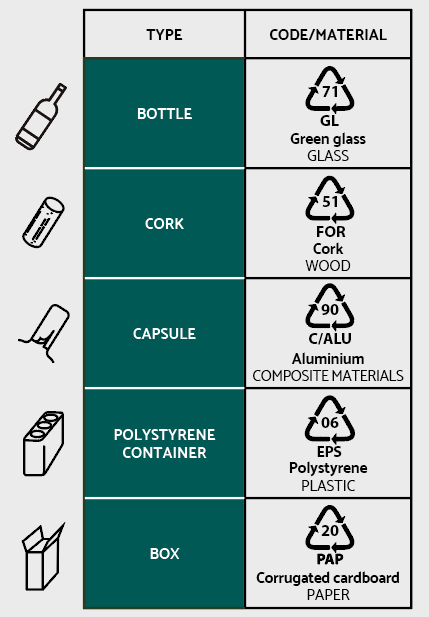

Glass, cardboard, cork, aluminium… as well as polystyrene, all the packaging materials we use to send our wine, and its contents, can be recycled: they just need to be put in the right bin.

To avoid mistakes, here are the international codes and groups for each material: for collection criteria, check the instructions of your local council or your country.